Industrial endoscope is a kind of detection instrument that helps humans break through the limitations of vision. It can assist inspectors in observing the conditions inside relatively closed or complex equipment and pipelines. It is widely used in detection tasks in the fields of aerospace, petrochemical, automobile manufacturing and maintenance, police security, energy and electricity, rail transportation, pipeline welding, etc. The high-definition industrial video endoscope introduced in this article belongs to industrial endoscope, but it has the word “high-definition”. Therefore, while it has the above commonalities, it also has its own special features.

Features of high-definition industrial endoscope

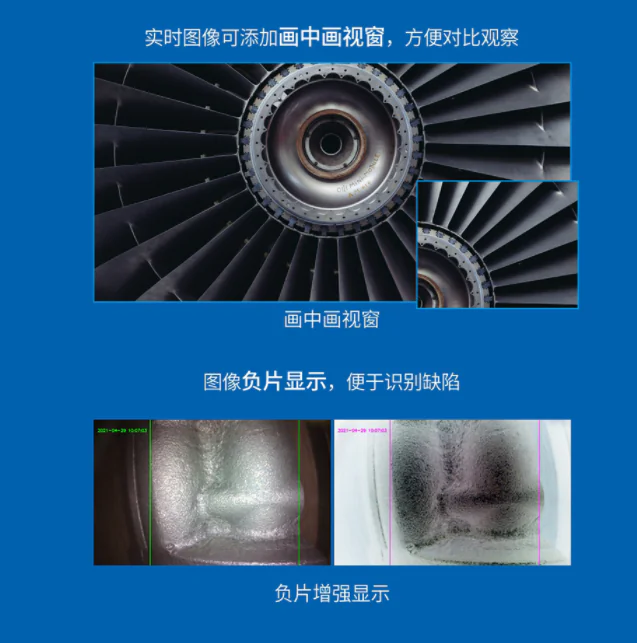

1. “Video”-The imaging principle adopts photoelectric conversion technology. Unlike straight-rod endoscopes and fiber optic endoscopes, the front-end imaging of video endoscopes uses photoelectric sensing equipment, namely: image sensors, which convert light signals into electrical signals, and the presentation, processing, and storage of back-end detection images are all digitally managed. In addition to being more convenient, it is easier for inspectors to view the detection images on the display screen without observing through the eyepiece.

2. “High-definition”-the image quality is taken to a higher level. Involving two aspects: clearer pixels and richer details, so it is convenient for inspectors to find and accurately identify more subtle defects during the inspection process.

3. More powerful measurement capabilities. High-definition image quality makes it possible to measure large-size defects more accurately, making advanced measurement technology a step further. Application of high-definition industrial endoscopes From the above characteristics, it can be seen that thanks to the high integration, observation comfort, and management convenience brought by digitalization, video endoscopes are more convenient to use. Coupled with high-definition imaging characteristics and powerful measurement functions, this equipment can not only be applied to the various fields mentioned at the beginning, but also can cope with more demanding inspection challenges. For example: aircraft engine borescopes, the aviation industry introduced the concept of “condition-based maintenance” in the hope of more accurate and efficient engine maintenance and maintenance, and to achieve safety and profit benefits. From qualitative defect detection to quantitative analysis of defect severity, more reliable inspection results are required. High-definition industrial video endoscopes can better meet the inspection needs of condition-based maintenance.