In recent years, the View Simple portable acoustic camera has become a new favorite of many domestic electric research institutes and power companies. By using acoustic cameras to detect the status of power equipment and visually diagnose abnormal noise defects of the equipment. The portable microphone array of Micro Easy View Simple has also been applied to the diagnosis of internal vibration and noise signal abnormalities in power equipment, especially for the localization of external abnormal noise.On February 15th, at the ultra-high voltage converter power station in Shandong Province, State Grid was using a new “weapon” to carry out acoustic testing of 750 kV GIS equipment AC withstand voltage test.

Acoustic imaging is based on microphone array measurement technology, which measures the phase difference of signals from sound waves in a certain space to each microphone, and determines the position of the sound source based on the principle of phased array. By using acoustic imaging technology, abnormal noise of electrical equipment during substation operation can be analyzed, and equipment defects caused by loose structures and uneven stress can be found. This is much more efficient than previous vibration testing The on-site work leader and personnel from the Network Source Technology Center of the Electric Power Research Institute introduced.

According to technical personnel, there are currently many methods for detecting corona discharge on high-voltage transmission lines in China, including infrared thermal imaging, ultraviolet imaging, ultrasonic corona detection, electromagnetic detection, and visual observation. However, due to complex terrain and strong ultraviolet radiation, the detection efficiency is relatively low, and the industry urgently needs a convenient and efficient detection method.

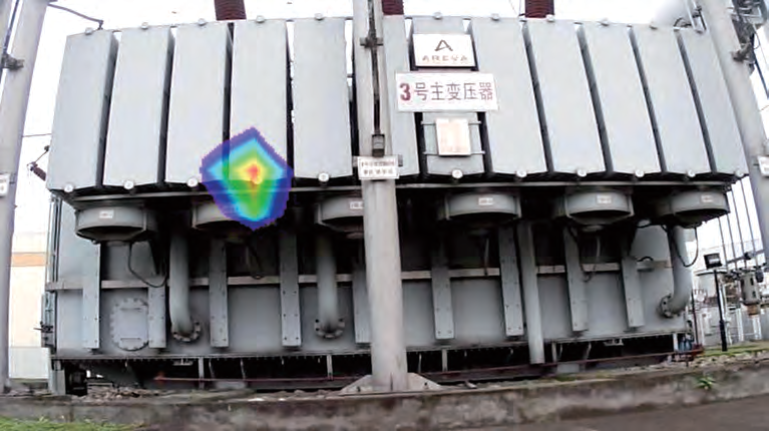

With the comprehensive resumption of work and production of various key construction projects in Shandong Power Grid recently, since March, Shandong Power Grid has used this sound imaging instrument to collect and record equipment noise signals for 330 kV and above substation overhead lines, equipment outgoing lines, transformers, reactors, and lightning arrester grading rings in GIS equipment areas that have resumed work and production in the province. The noise signals are located using “micro easy to see” sound imaging calculation and analysis software, Simultaneously, infrared thermal imaging, visual observation and other methods are used to collect images of noise sources, and the reasons for noise generation are analyzed based on equipment operating parameters and relevant inspection records.

It is understood that this is the first application of this equipment in the construction of the Shandong power grid, and the use of this equipment for corona discharge detection has the characteristics of “new, accurate, and fast”. The detection technology is new, and the application of acoustic imaging technology to the status detection of electrical equipment in substations is still the first time in Qinghai Province, with a wide range of future application scenarios; Accurate noise localization, based on high sensitivity microphone array measurement technology, capable of accurately locating abnormal sound sources; The detection efficiency is high, and compared to traditional detection methods, the imaging range of the acoustic imager is larger. Through online analysis, corona or other abnormal sound sources can be located in real-time, helping detection personnel quickly grasp the operation status of the circuit and equipment.