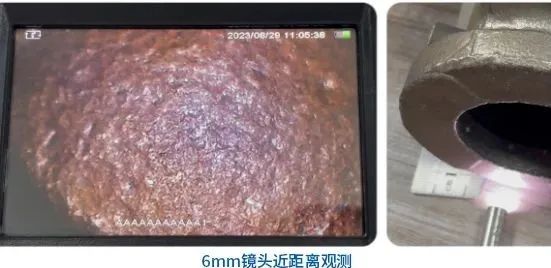

The market size of the industrial endoscope industry is gradually expanding. Industrial endoscopes are constantly innovating and improving, showing a development trend of high resolution, wide field of view, miniaturization and intelligence. Nowadays, although industrial endoscopes have developed from the initial viewing, taking pictures, and recording functions to the current mainstream three-dimensional measurement endoscopes for measuring defects and sizes. However, it is still not convenient enough to use in some specific working conditions. For example, when inspectors inspect aircraft engine blades and the internal structure of the combustion chamber, due to complex characteristics, they need to replace lenses with different depths of field of near focus, medium focus, and far focus or replace pipelines during the inspection process to solve this inspection problem. In order to break the current situation that the depth of field of the lens can only be “fixed focus” but not “zoomed”, Jiaruisida launched the “electric optical zoom lens”, which announced that data can be obtained quickly and accurately in subsequent inspections, and it is more focused on the inspection itself, breaking the traditional situation that only by replacing lenses or pipeline systems can different focal length inspection requirements be met. The 6mm lens zoom technology was initially based on SVD high-definition industrial endoscopes, and can be installed on other products in the future. The equipment uses micro/high-precision long-range digital zoom technology, which can achieve high-precision observation from 6mm to infinity. Lens zoom is an important function of industrial endoscopes. It can change the focal length of the lens within a certain range. Specifically, the zoom lens is composed of multiple groups of lenses. When the lens zooms, these lenses will move back and forth, changing the main optical axis of the lens, thereby changing the focal length. This change allows us to present the observed object in a clearer and more three-dimensional way without changing the object distance. At present, we have mastered advanced technologies such as lens replacement, manual optical focus lens, and automatic optical focus lens. These advanced technologies will make the application of industrial endoscopes in industrial inspection more extensive, efficient and accurate, and can help engineers see the internal conditions of components more clearly.