Beijing Jiaruishida Technology Co., Ltd. SVM Pro measuring industrial endoscope assists nuclear power plant safety inspection

Recently, Beijing Jiaruishida Technology Co., Ltd.’s SVM Pro measuring industrial endoscope has played an important role in nuclear power plant inspection, providing strong technical support for the safe and stable operation of nuclear power facilities.

As a clean and efficient energy source, nuclear power occupies an important position in the energy structure. The safe and stable operation of nuclear power plants is crucial, and the internal quality inspection standards and requirements of their pipelines are extremely strict. As an important non-destructive testing tool, industrial endoscopes play an irreplaceable role in many key links of nuclear power plants.

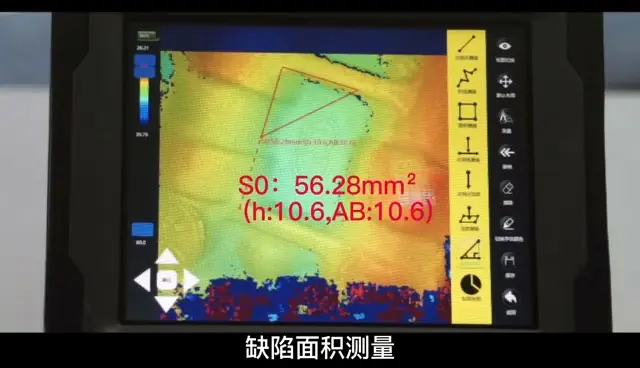

In the pipeline welding quality control of a nuclear power plant, the SVM Pro measuring industrial endoscope has demonstrated excellent performance. Using its high-definition video image function, the inspectors clearly and intuitively found a subtle unfused defect in a weld. If this defect is not discovered in time, it may cause pipeline leakage in a long-term high temperature and high pressure environment, seriously threatening the safe operation of the nuclear power plant. The precise detection of SVM Pro allows staff to repair defective parts in a timely manner, ensuring that the welding quality meets strict standards. At the same time, in the same pipeline inspection, it also promptly discovered a small amount of welding slag remaining in the pipeline, avoiding the adverse effects of these foreign objects on the subsequent system operation.

During the system debugging stage, another nuclear power plant quickly located the sediment accumulation problem in the cooling system pipeline with the help of SVM Pro. Through the endoscope image, the inspectors clearly saw the sediment attached to the inner wall of the pipeline, providing an accurate basis for subsequent cleaning work and ensuring that the system was in the best condition before operation. During an overhaul after the nuclear power plant was put into operation, SVM Pro conducted a detailed inspection of the valve and successfully identified a potential safety hazard of slight wear on the valve sealing surface, which built a solid line of defense for the safe and stable operation of the nuclear power plant.

In addition, facing the complex and diverse inspection environment of nuclear power plants, the SVM Pro measurement industrial endoscope has the characteristics of one machine for multiple uses, and can quickly replace lenses of different specifications and performances from 3.0 to 8mm to meet the inspection needs from narrow pipelines to large-space pressure vessels and pipelines. For environments with dim light or requiring high-brightness lighting, its high-brightness adjustable light source can effectively improve image clarity and contrast, making inspection work more efficient and accurate.

The relevant person in charge of Beijing Jiaruishida Technology Co., Ltd. said that the successful application of the SVM Pro measuring industrial endoscope in the nuclear power plant is a reflection of the company’s technical strength. In the future, the company will continue to increase R&D investment, continuously improve product performance, and provide high-quality solutions for safety testing in more industries. With the continuous advancement of science and technology, the application prospects of industrial endoscopes in the nuclear power industry will be broader, and it is expected to make greater contributions to the safe development of the nuclear power industry.